|

|

|

Welcome to the Inside Track with ARC. The Auto Research Center is a specialized research facility serving the motorsport, production, commercial, government and bicycle industries. The ARC global headquarters is located in Indianapolis, Indiana which hosts their 50% scale wind tunnel, 7-post, drivetrain test rig, bicycle test facility and CFD cluster center. ARC offers a wide range of solution packages to further speed and efficiency.

ARC 7-POST FEATURES NEW UPGRADES

ARC is upgrading its 7-Post aero loaders to the electric feedback (EFB) servo valves from Servotest. The Servotest rig is already class leading with its ability to apply a Ride-Height dependent aeromap instead of simply applying a static force.

The EFB valves will allow for quicker changes of the applied force thus making the replication of aerodynamic forces even better. Users of the rig will gain more understanding on how platform control affects the cars downforce, thus improving track correlation.

We are planning on having this feature implemented early in 2016 so start booking now by calling 317-291-8600 or emailing sales@arcindy.com to improve your track times.

To learn more about ARC's offerings for the Bicycle and Motorsports Industry, visit the ARC website.

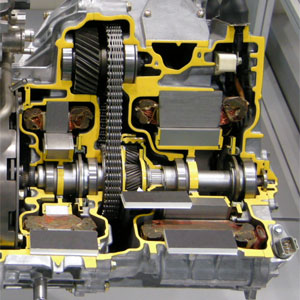

HYBRID TRANSMISSION TESTING BEING DEVELOPED FOR ARC'S DRIVETRAIN TEST RIG

Developing and verifying hybrid drives requires a new level of technology from driveline test rigs. The ARC driveline is ready for the task using Bosch-Rexroth Secondary Control Technology. Secondary Control allows hydraulic systems to quickly switch from absorption to driving thus the ARC rig can replicate realistic drive cycles in order to optimize hybrid drives. Manufacturers of hybrid drive systems will be able to work on their regenerative braking control strategies by using the ARC driveline rig in drive cycle replication mode. ARC engineers are currently working on this upgrade which will be up and running by early 2016.

With the ARC driveline dyno's ability to quickly change out drivelines, several different designs could be tested without having long downtime delays while making large transmission setup adjustments, allowing for more innovation in a quicker timeframe. If you are interested in the hybrid drive system, let us know by calling 317-291-8600 or via email at sales@arcindy.com. For more about the drivetrain test rig, visit the ARC website.

To learn more about ARC's offerings for the Production Car OEM Industry, visit the ARC website.

NACFE TRUCKING CONFERENCE AT ARC ON DECEMBER 9TH

Be sure to come to ARC on December 9th to attend the NACFE (North American Council for Freight Efficiency) workshop on trucking efficiency, including getting actual wind tunnel data from the ARC rolling road wind tunnel, an approved EPA Smartway test facility.

Read more about it on the ARC website and register today.

The event schedule:

| 8:30 am |

Registration |

| 9:00 am |

Presentation by ARC on Fuel Efficiency Validation including Wind Tunnels |

| 9:30 am |

Tour, including watching wind tunnel tests of Tractor Trailers |

| 10:30am |

Kick off workshop with a welcome and introductions |

| 11:00am |

Leader Dialogue: TBD: the EPA and Manufacturers Invited |

| Noon |

Lunch & Networking |

| 1:00 pm |

Technologies and Confidence Reports |

| 1:30 pm |

Small Group Table Discussions (8) |

| 3:45 pm |

ARC Reports on Wind Tunnel Data Results |

| 4:15 pm |

Wrap up & Networking |

To learn more about ARC's offerings for the Commercial Industry, visit the ARC website, call 317-291-8600 or email at sales@arcindy.com.

|

|

TECH ZONE

How do you scale heat exchangers for the ARC wind tunnel?

While heat exchangers cannot be directly scaled for wind tunnel usage, they can still be accurately created. The most important element to creating a representative heat exchanger is the pressure drop chart. All manufactures of heat exchangers have this on file for every core type and size.

Several methods can be used to create the pressure drop between the front and back face of the heat exchanger, the most common is to use a perforated plate. Using actual core material has also been explored. Both methods require some physical testing to select the correct blockage to match the required pressure drop. This testing is done either using a flow rig or in the actual wind tunnel with the heat exchanger installed in the model. All scale model heat exchangers are built to allow easy changing blockage to test different pressure drop effects on aerodynamics.

TECH ZONE is an additional area of our newsletter where each month a customer question will be answered by the related expert at ARC. Please send in any questions you might have, from wind tunnel test instrumentation, CFD workings,to tuning your shocks.

Ask your questions at techzone@arcindy.com

|

|

|

|

|

|